Hydrogen fuel cells promise reliable power, zero emissions

As governments worldwide increase their focus on carbon emissions targets, organisations are responding with ambitious decarbonisation plans, accelerating the adoption of alternative energy sources.

Hydrogen is increasingly recognised as a potential source of clean energy since it is carbon neutral at the point of use. However, its production is currently heavily dependent upon fossil fuels, and global CO2 emissions from hydrogen production are currently estimated to be around 830 million tonnes annually.

Countries in Southeast Asia, (SEA), currently account for around 3% of global hydrogen production, mainly using coal and natural gas, and therefore contribute significantly to these emissions. Although many observers are sceptical about the practicality of developing hydrogen as a clean energy source, significant investments are planned, both globally and within SEA, to scale-up the production of green hydrogen. As a supplier of reliable energy backup systems, Kohler is keenly aware of the growing need to integrate renewable energy sources into our solutions. While continuing to improve the sustainability of our traditional diesel generators, we are actively seeking innovative ways of providing our customers with sustainable energy resilience.

In this article, we review the evolution of hydrogen as a fuel in industry before looking at our ongoing investments in hydrogen fuel cell technology.

The Evolution of Hydrogen as an Industrial Energy Source

The use of hydrogen as an energy source is not new. Although it was first recognised as an element in 1766, there are indications that it was being produced around two hundred years earlier.

Today the supply of hydrogen for industrial use is a major global business, with demand reaching 95% in 2022, up more than 3% over the previous year. This demand is heavily concentrated in traditional applications in refining and industrial sectors, with very limited penetration in new applications.

Although hydrogen's energy density is low compared to traditional fuels, its full value is realised when converted to derivatives. When combined with carbon from CO2, Hydrogen can be used to produce hydrocarbons. It can also be used to produce ammonia for fertilisers, methanol, synthetic fuels, and as a reducing agent in iron production, effectively replacing coal. These conversions increase the energy density and value of hydrogen and overcome some of the infrastructure challenges related to its transportation and storage.

The use of hydrogen as an energy carrier is currently very limited, mainly confined to fuel cells in transportation. As of June 2021, there were over 40,000 fuel cell vehicles on the roads globally, with a major proportion of these in Asia countries – specifically Korea, China, and Japan.

Despite its current status as a significant emitter of CO2, there is growing recognition of the potential of producing hydrogen from renewable energy sources.

Hydrogen Production

As discussed above, hydrogen production is currently a major source of CO2 emissions, at a level which is unsustainable given its projected growth in demand. Hydrogen is currently classified using a colouring system, with black or brown denoting the "dirtiest" production methods, using gas or coal. At the other end of the spectrum, green hydrogen is emerging as a viable, clean production method, although multiple challenges remain before it becomes a viable option at scale.

Green hydrogen production is based on technologies such as electrolysis, which splits water into its Hydrogen and Oxygen components using high-voltage DC currents. A hydrolysis plant can use multiple electricity sources to power the process, including the grid, wind, solar and batteries. As more renewables are integrated into electricity grids the proportion of hydrogen produced using clean energy will increase.

Overcoming the challenges in green hydrogen production

Although green hydrogen is a promising source of clean energy, only around 2% of hydrogen is currently produced by electrolysis, and a number of challenges are hindering its adoption. Electrolysis is expensive and requires significant investment in infrastructure, production facilities, storage, transportation, and distribution networks. According to the International Energy Agency, current production costs for green hydrogen are anywhere between $3 and $8 per kilogram, compared with $0.5 - $1.7 per kilogram for brown hydrogen, (using natural gas) and $2.5 for black hydrogen, (using coal).

This situation will change, however, as governments encourage developments in clean energy in general and green hydrogen in particular. Global investments are focusing on increasing the scale of electrolysis plants and by 2050, 60% - 80% of global hydrogen supply is expected to be decarbonised. Within the Asia region countries including Japan, Singapore, Indonesia, and Malaysia are actively engaged in projects to develop green hydrogen infrastructure.

Hydrogen fuel cells

Hydrogen fuel cells are a clean and efficient method of producing electricity, using the chemical energy of hydrogen, with the only other products being water and heat. Fuel cells can operate at higher efficiencies than Internal Combustion Engines, up to 60% and over, and are suitable for a wide range of applications, providing power in sectors such as transportation, industrial/commercial/residential buildings. Capable of providing power for systems as large as a utility power station or as small as a laptop, fuel cells also have promise as energy storage in reversible grids systems. With moving parts, fuel cells produce very little noise during operation and do not produce CO2 emissions or any other pollutants. They also operate like batteries, although they do not run down or need recharging, producing heat as long as fuel is supplied.

Figure 1: How a fuel cell works

Figure 1 illustrates the operation of a typical fuel cell. Hydrogen (H2) atoms enter at the cell's anode and oxygen (O2) at the cathode. The hydrogen atoms are separated into protons and electrons at the anode and the positively charged protons pass through a membrane, or electrolyte, to the cathode. The negatively charged electrons take a different path, being forced through a circuit to generate electricity. After assessing through the membrane and circuit respectively, the electrons and protons meet at the cathode where they combine with the oxygen to produce heat and water.

The specific characteristics of the fuel cell are dictated by the material used in the membrane. Polyme Electrolyte Membrane (PEM), fuel cells use an acid membrane and a solid polymer as an electrolyte, with porous carbon electrodes containing a platinum or platinum alloy catalyst. The electrical efficiency of these fuel cells is around 45% to 65% and they are characterised by fast start-up times and low operating temperatures and are smaller and lighter than other fuel cells.

Although hydrogen fuel cells are beginning to be deployed in vehicles, as described above, several challenges need to be overcome before their use becomes widespread. As we saw earlier, hydrogen extraction requires large amounts of energy, undermining any green benefits from the cells. Cost is also an issue, mainly due to the materials used in the catalyst. Finally, significant investment is required in infrastructure to support growth fuel cells, including the development of fueling stations, retrofitting vehicles and to address the numerous safety issues surrounding such a flammable material.

KOHLER and hydrogen

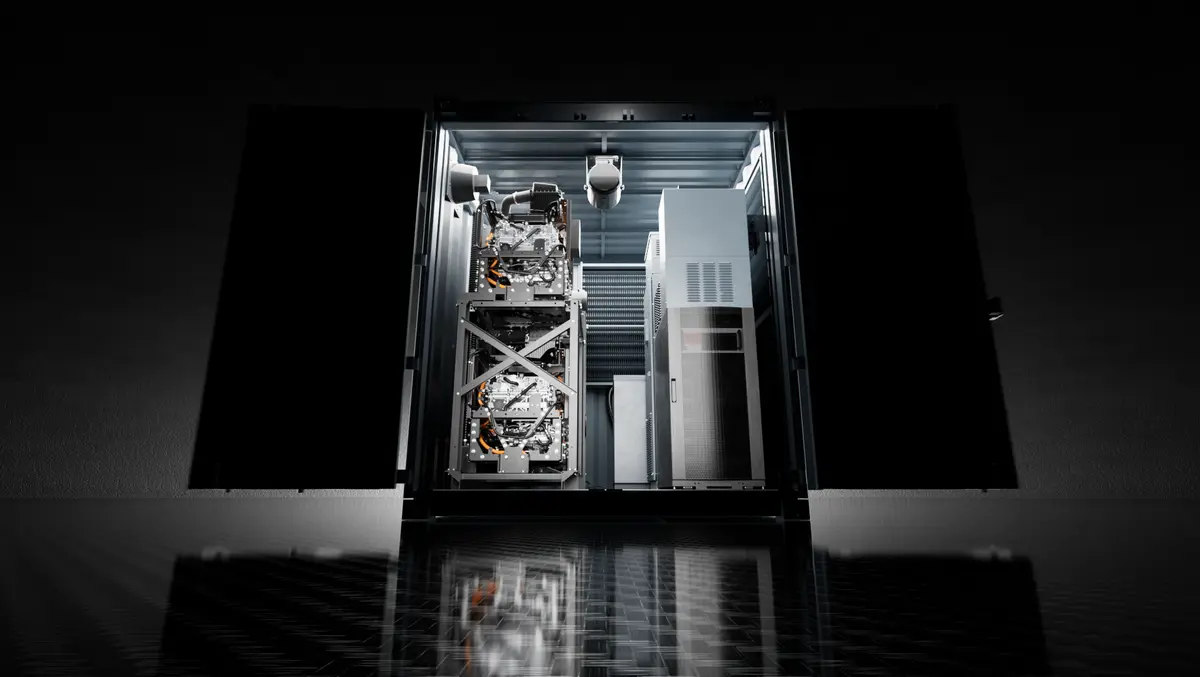

Figure 2: KOHLER hydrogen fuel cell power system

Within our power systems business, Kohler is focused on providing our customers with sustainable energy resilience to our customers. We recognise the potential that hydrogen fuel cell technology has to enable our customers to reduce emissions without compromising their mission-critical power supplies. Our ongoing investment and acquisitions strategies are geared towards building the resources and expertise to enhance the sustainability of our operations and products.

Ongoing developments include the KOHLER hydrogen fuel cell system, figure 2. This modular and scalable system enables our mission-critical power customers, including data centers, utilities, ports, airports, and wastewater treatment plants, to rapidly deploy a sustainable energy solution. The Kohler hydrogen fuel system is available as a prime or backup power source, for peak saving, or as part of a distributed energy network.